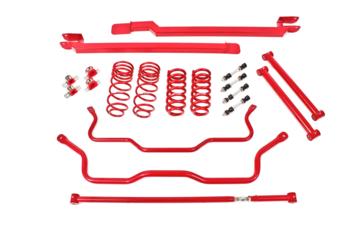

93-02 Fbody BMR Suspension Handling Performance Package (Level 1)

$1,409.00

Model Number: HPP005BMR Suspension has taken the guesswork out of making significant handling improvements to the Fourth Gen GM F-Body, and put it in one convenient package. Countless hours of design, engineering, and track testing gives you the best combination of parts for improved handling on the street and track. Matching specific components provides a great blend of performance, aesthetics, and comfort.

BMR’s Level 1 Handling Package (HPP005) addresses key points of the suspension to improve the “system.” BMR Suspension designed the HPP018 to work well for street performance and handling applications. Whether you simply want a better handling daily driver, or the ultimate track day car, rely on BMR Suspension!

Lowering Springs (SP001)

BMR Suspension believes the right springs go beyond looks—your F-body needs to perform, too! All BMR springs are manufactured from chrome silicon high-tensile spring wire, and are cold wound on a CNC coiling machine. The CNC coiling head can adjust the spring diameter in real time to ensure that every spring is exactly the same. This guarantees that your right spring matches your left spring. Every BMR spring is compressed solid at the factory, not once, but twice. This gives the spring its permanent set, and guarantees no sag. BMR springs are stress-relieved at 750 degrees F, ensuring most stresses induced during the winding process are eliminated. All springs are then shot-peened to eliminate residual surface stresses. Many spring manufacturers skip this step, but BMR insists on this operation as part of our spring manufacturing process. Every spring is computer tested as the last step—every spring, not just a sample from each batch. Each spring is loaded in the spring tester at the factory, then compressed and the CNC load cell measures the force for a variety of spring lengths. This allows BMR to offer a LIFETIME WARRANTY against spring sag.

Blending aesthetics and performance, BMR has designed the SP001 for the street performance crowd who want to use their cars in a variety of application. These springs will drop the front end of your GM F-body 1.25-inches, and feature a fine-tuned spring rate to give you great handling and a smooth ride. The linear spring rate offers plenty of support, keeping the body flat and level in the corners, while remaining soft enough for a comfortable ride on any road.

Sway Bars (SB026)

Stock sway bars have low torsional spring rates because they are manufactured from small diameter bar stock or tubing. BMR Suspension’s SB026 front and rear sway bar kit was designed by factoring in the vehicle weight, application, motion ratio, coil spring rate, and adjustability requirements. Manufactured from heavy-wall 35mm (front) and 25mm (rear) DOM tubing, the SB026 is cold formed to better resist torsional fatigue and retain its “memory” far longer than the hot-formed bars used by many competitors. The sway bar is CNC-formed for exact manufacturing tolerances and repeatable high quality. The sway bar mounts to the car using polyurethane bushings. These bushings are molded from 88-durometer, low-deflection, polyurethane, and are internally fluted to keeps grease in the bushing. The steel sway bar mounting brackets are reinforced to minimize deflection.

BMR Suspension designed the SB026 sway bar for street performance, autocross, and road race applications. The large sway bar give you the ability to drive to and from the road course or autocross and still out handle the competition with the same sway bar. The SB026 sway bars give you a 129% increase (front) and a 149% increase (rear) in sway bar rate. These rate increases allow you to drive harder through corners with minimal body roll. The hollow design allows for loads of strength in the lightest package possible. This means increased performance with no sacrifices. The SB026 attaches to your F-body with 88-durometer polyurethane bushings, reducing the deflection from the stock rubber bushings. This allows for more sway bar control, and more control equals better handling.

Panhard Bar (PHR002)

Factory GM F-Body Panhard rods are made from weak U-shaped stamped steel with soft rubber bushings that allow excessive deflection under load. BMR Suspension’s PHR002 Panhard rod is made 1.25-inch, 0.120-inch wall DOM tubing with TIG-welded chrome-moly tube adapters. The PHR002 features BMR’s CNC-machined center adjuster, which is made from 4130 chrome-moly with rolled threads. Greasable, 95-durometer bushings add a solid, more responsive feel over the stock rubber bushings. BMR’s bushings are internally fluted, which allows grease to evenly coat the inner sleeve, keeping grease in the bushing under high compression loads. These flutes also direct grease to the outer edge of the bushing, keeping the thrust surface lubricated. This efficient lubrication ensures quiet, reliable operation over the life of the bushings.

BMR Suspension designed the PHR002 to work well for street performance, drag race, and road race applications. The heavy-duty construction eliminated the deflection seen in stamped-steel Panhard rods. Other Panhard rods on the market include rubber bushings that will deflect under heavy loads. The 95-durometer polyurethane bushings of the PHR002 reduce bushing deflection, giving you much-improved, repeatable handling characteristics on the street, starting line, or in aggressive corners. The chrome-moly center adjuster makes the PHR002 on-car adjustable, so all adjustments can be made without removing the Panhard rod. This gives you all the adjustability you need for great handling without huge increases in NVH.

Subframe Connectors (SFC001)

Reduce chassis flex to a minimum and increase your handling capabilities with a set of BMR subframe connectors. These weld-in subframe connectors fit 1993-2002 F-bodies and will work with all aftermarket exhaust systems. All mounting plates are made from either 3/16″ or 1/4″ laser cut plates for the ultimate in strength. Boxed connectors use 2″ square tubing.

Lower Control Arms (TCA001)

BMR’s polyurethane, non-adjustable tubular control arms for F-bodies are the ultimate is strength. Stock stamped steel control arms with soft rubber bushings deflect under load and absorb power instead of transferring it to the tires. Manufactured from heavy-duty 1¼-inch, 0.120-inch wall steel tubing, the TCA001 polyurethane lower control arms nearly eliminate all control arm deflection. Greasable, internally fluted, 95-durometer bushings add a solid, more responsive feel over the stock rubber bushings. BMR’s bushing design allows grease to evenly coat the inner sleeve, keeping grease in the bushing under high loads. These flutes also direct grease to the outer edge of the bushing, keeping the thrust surface lubricated. This efficient lubrication ensures quiet, reliable operation over the life of the bushings.

The stock control arms flex under cornering loads giving you inconsistent handling characteristics. Combine this with soft rubber bushings that have massive amounts of deflection and you’re left with poor performance. The TCA001’s heavy-duty construction and polyurethane bushings eliminate unwanted deflection, giving you much improved repeatability on the street, starting line, or in the corners. BMR’s polyurethane bushings are compliant enough to give you a comfortable ride and absorb NVH, while remaining firm enough to stand up to high loads of any performance environment. The bushings easily handle the high compression loads of hard launches and hard acceleration, yet offer plenty of articulation for great handling. These are the perfect upgrade for the enthusiast looking to improve performance at an affordable price, while maintaining acceptable NVH levels and ride quality. BMR Suspension designed the TCA001 to work well in street performance, drag race, and road race applications.

Buying the package SAVES over $60!

BMR Suspension’s HPP005 Level 1 Handling Package is available in black hammertone and red powdercoat for long-lasting good looks. Installation time is 3-4 hours. Proudly made in the U.S.A.

| Color |

|---|

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.